Build a high-end comprehensive integrated processing supporting service provider

National free service hotline

400-0537-697

Steel Welding

Hisure Heavy Industry has established a strategic partnership with Germany's renowned welding company - Klemm Corporation, introducing advanced steel welding equipment, manufacturing processes, and testing instruments. Currently, the company possesses 25 imported welding machines including German Rehm welders and Cloos welders, 2 imported cutting machines such as German Messer CNC flame cutting machines, and 2 German plasma cutting machines, forming a complete technical chain from design to manufacturing. The company is capable of handling large welding components up to 16 meters in length, 5 meters in width, 4.5 meters in height, and 100 tons in weight, providing extensive services in the fields of general machinery, specialized equipment, and metal structural component manufacturing.

Steel Welding Workshop

The complete set of steel welding technology and processes is imported from Germany, with a team of engineers boasting 30 years of welding experience, 15 structural and process R&D personnel, and 20 welding technicians with over 10 years of experience. The workshop covers an area of over 10,000 square meters, primarily engaged in the design and manufacturing of general and specialized mechanical equipment components, metal structural components, offering clients a comprehensive procurement solution including design, manufacturing, and assembly.

Equipment and tools

The company is equipped with two Messerschmitt flame cutting machines with cutting ranges of 15 meters and 24 meters respectively, maximum cutting thickness up to 350mm, monthly cutting capacity up to 600 tons, efficiently meeting various large-scale plate processing demands.

The company also possesses heavy-duty welding workstations and 3D flexible platforms, with the 3D flexible platform team achieving precision up to 0.5mm, ensuring high precision and stability in welding operations, providing exceptional support for complex structural component manufacturing. Flexible equipment combinations comprehensively guarantee production efficiency and quality.

Messerschmitt flame cutting machine

Two Large Flame Cutting Machines

Maximum Cutting Thickness: 260mm

Monthly Cutting Capacity: 600 tons

Bevel

Reverberatory furnace

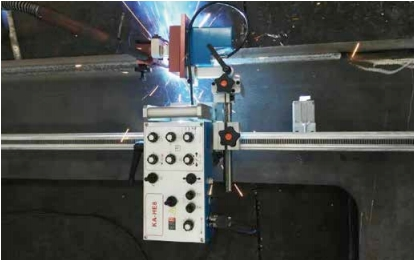

Long-distance seam electric semi-automatic welding

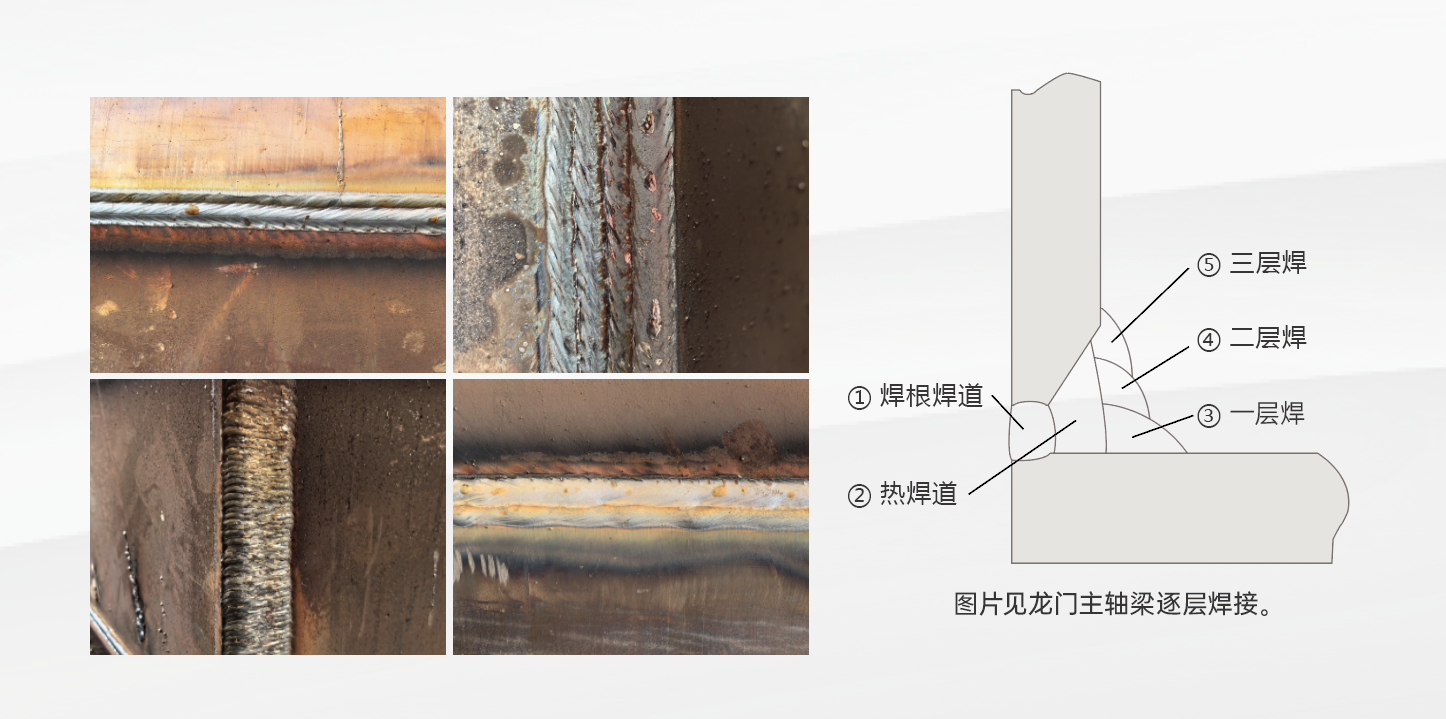

Layer welding

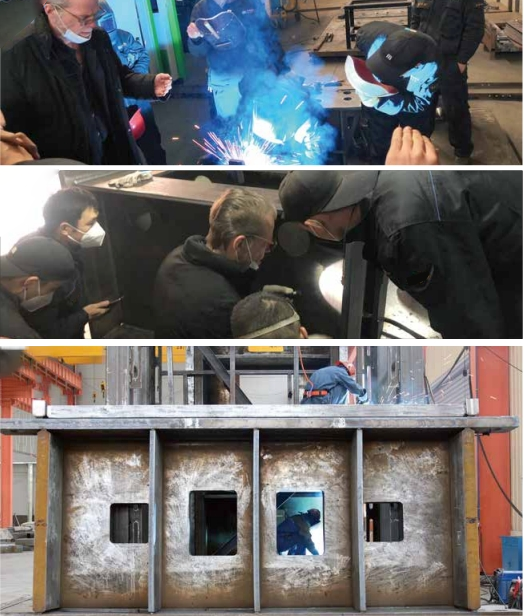

Welding process guidance

We have skilled welders with rigorous technical training, a comprehensive monthly quality assessment mechanism to ensure stable daily welding operations. Welding engineers with 30 years of experience focus daily on improving and enhancing welding techniques.

Case Studies

Ready to discuss your project?

Ueeshop WeChat

Learn about our team's daily operations